You might wonder whether it’s possible to embark on the journey of making your own vinyl records.

The good news is that creating custom vinyl is indeed an achievable task, although it requires access to specific equipment and expertise.

In Summary

DIY Vinyl Pressing: Individuals can create their own vinyl records using specialized cutting machines, though these are typically expensive and require technical knowledge.

Custom Pressing Services: Numerous companies offer custom vinyl pressing services, allowing you to send in your music and have it professionally pressed onto vinyl.

Quality Considerations: Self-made vinyl records may not match the sound quality of professionally pressed records due to differences in equipment and expertise.

Legal Aspects: When creating vinyl records, it’s crucial to have the rights to the music or content being pressed to avoid copyright infringement issues.

The process of pressing a vinyl record involves several intricate steps that have remained relatively consistent since their inception.

Music is first recorded and mastered, usually in a digital format, before being transferred onto a lacquer disc in a process known as cutting.

This lacquer disc is then used to create a stamper, which will press the grooves into the vinyl discs, imprinting your music onto the final product.

While historically this was a process reserved for professional pressing plants, recent technological advancements and the rise of smaller independent presses have made it more accessible.

However, it’s important to understand that pressing vinyl records is not as simple as printing a document at home; it demands a certain level of investment and commitment.

Whether you’re looking to press a few copies for personal use or considering a larger-scale production for wider distribution, knowing these basic aspects of the vinyl pressing process can guide you in the right direction.

Of course, if you’re looking into doing this yourself, you’ll delve deeper into the specifics of the process, materials, and equipment required.

The Basics of Vinyl Record Creation

Creating your own vinyl records involves a detailed process, primarily using polyvinyl chloride (PVC) as the base material. You’ll need to comprehend the dynamics of the vinyl itself and the intricacies of the record cutting process.

Understanding the Vinyl Material

Vinyl records are made from polyvinyl chloride, a plastic compound that offers both durability and the necessary flexibility to capture sound grooves. Your records start as PVC pellets, which are melted and then formed into a platter.

This platter acts as the foundation for the music that will eventually emanate from your turntable.

Overview of the Record Cutting Process

The journey from audio file to vinyl begins with the record cutting process. Here, a master disc, commonly known as an acetate, is used.

An engraving needle etches audio grooves into its surface, mirroring the original recording’s waveforms. Your music is physically imprinted onto the acetate, one groove at a time, requiring precision to ensure the highest sound fidelity.

Once the master disc is complete, it serves as a template to stamp copies onto vinyl platters, creating your unique vinyl records ready for the turntable.

Customization Options for Personal Vinyl Records

Creating personalized vinyl records allows you to express individuality both in sound and appearance. Whether you are a musician aiming to offer fans something unique or a vinyl enthusiast looking to put your stamp on a private collection, customization is key.

Adding Personal Touches to Center Labels

Center labels on vinyl records are more than just informational. They offer a canvas for personalization. When you decide to create your custom vinyl, consider choosing a design or adding a photo that reflects the essence of the music or represents your personal brand.

Companies often provide templates, but for something truly yours, upload your original design or image that speaks to the heart of your work.

Creating Custom Cover Art

The cover art of your vinyl is the first thing people see; it can capture the spirit of the album and intrigue listeners. To customize your vinyl record’s cover, select imagery that tells a story, engages onlookers, or complements the music within.

You can use high-quality photos, illustrations, or graphical designs to craft a cover that stands out. Be sure to adhere to the printing specifications to ensure a crisp, clean result.

The Technical Side of Making Vinyl Records

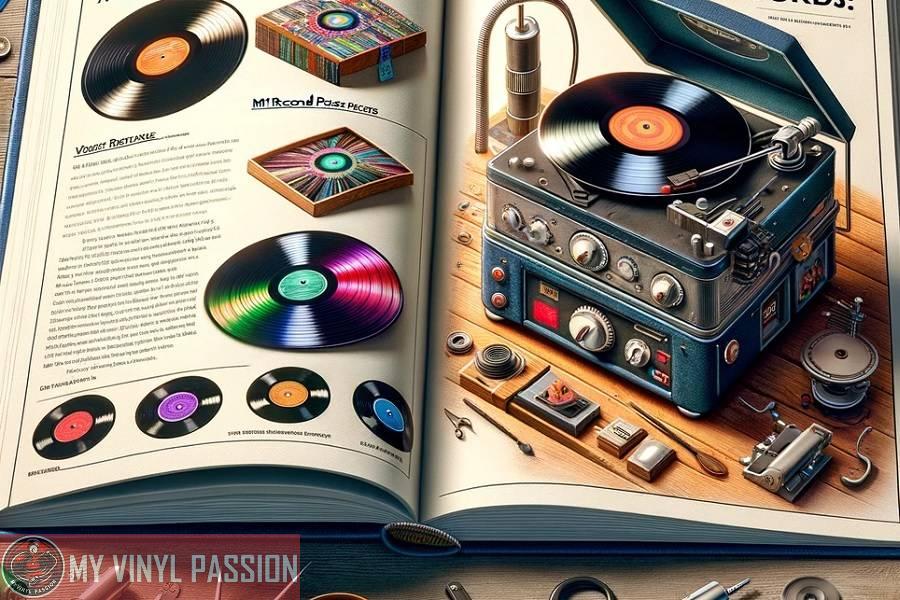

Creating your own vinyl records is a detailed process that involves a choice between lathe cutting and pressing, as well as substantial knowledge about the necessary equipment and tools.

Understanding Lathe Cut vs. Pressed Vinyl

Lathe cutting and pressing represent two distinct methods for producing vinyl records.

Lathe cut records are created individually, using a recording lathe equipped with a diamond stylus that etches sound grooves directly onto the surface of a blank disc.

This custom method is often used for small runs, producing unique and limited-edition records. Designers like Yuri Suzuki have contributed to the accessibility of lathe cutting with devices such as the Phonocut, which allow for at-home vinyl cutting.

On the other hand, pressed vinyl involves creating a master disc first, which is then used to press the sound grooves onto multiple records through a hydraulic press.

While more complex and requiring a larger setup, pressing is ideal for larger quantities and can be more cost-effective per unit when mass-producing records.

Equipment and Tools for DIY Vinyl Cutting

To embark on cutting your own vinyl records, you’ll need specific equipment:

- Record Cutters: Devices such as the Phonocut are designed for personal use, enabling you to create lathe cut records from digital audio files.

- Cutting Stylus: A diamond stylus is essential for inscribing audio grooves with precision. Its durability and sharpness affect the quality and clarity of the playback.

List of Essential Tools for Vinyl Cutting:

- Lathe or vinyl cutter (e.g., Phonocut)

- Cutting stylus (preferably diamond-tipped)

- Blank vinyl discs

- Audio source and playback system

- Pre-amplifier (if not built into the cutter)

To execute the cutting process, you’ll follow these steps in sequence:

- Prepare your audio source.

- Ensure all equipment is properly calibrated.

- Begin the cutting process, monitoring for consistent groove spacing and depth.

- Test the playback for quality assurance.

Remember, precision is vital in each step to produce a high-quality custom lathe-cut vinyl record.

Purchasing and Using Vinyl Record Cutters

Vinyl record cutters offer you the unique opportunity to craft your records at home, allowing for a highly personalized touch to your music collection. To ensure the best results, investing in the right equipment and understanding how to use it will be critical.

Choosing the Right Vinyl Cutter for Home Use

When selecting a mini record cutter, there are several features to keep in mind. Look for a cutter with a robust cutting arm and a quality ceramic cartridge to ensure clean grooves and sound fidelity.

An integrated speaker could be beneficial for immediate playback, but may not be necessary if you have an external sound system. Additionally, a stable tonearm is essential for accurate tracking and minimizing distortion during the cutting process.

- Tonearm Quality: Seeks detail on material and balance.

- Cartridge Type: Determines output quality; ceramic is common.

- Additional Features: Integrated speaker for previewing.

Durability and ease of use are key for home users, and consider the compatibility with different sizes of vinyl records, as well as the type of vinyl you plan to cut. Here is a summary of what to consider:

| Feature | Importance | Notes |

|---|---|---|

| Cutting Arm | High | Must be precise and durable |

| Tonearm | High | Ensures accurate tracking |

| Cartridge | High | Affects sound quality |

| Integrated Speaker | Optional | For immediate playback |

Mini Record Cutter and Phonocut Vinyl Presser

Mini record cutters are compact and generally more affordable, making them ideal for enthusiasts beginning to explore vinyl creation. Despite their size, they can offer a high level of precision and quite satisfactory results for smaller projects.

On the other hand, the Phonocut Vinyl Presser is an excellent step-up choice that bridges the gap between hobbyist and professional quality.

The Phonocut is designed to be user-friendly, requiring minimal technical knowledge to operate. Its cutting technique delivers a depth of groove that can compete with factory-produced records.

- Phonocut Vinyl Presser: User-friendly, professional-level grooves.

- Mini Record Cutters: Ideal for beginners, excellent for small-scale projects.

Remember, the quality of your self-cut vinyl records will largely depend on the quality of the cutter you purchase, so it’s important to invest wisely based on your needs and the scale of your projects.

Beyond the Record – Merchandising and Extras

To maximize the impact of your custom records, consider expanding your offerings to include bespoke merchandise and playful extras like gift cards and stickers.

These additions not only enhance the overall aesthetics but also inject a personal touch that resonates with your audience.

Designing Merchandise Around Your Vinyl

Merchandise Options:

- T-shirts

- Posters

- Tote bags

When designing merchandise to accompany your vinyl records, it’s essential to maintain a cohesive theme that aligns with your record label or art project. Begin by choosing a color scheme and graphics that represent your music’s brand.

High-quality, eye-catching designs on T-shirts or posters can turn your music listeners into walking billboards for your brand.

Considerations for Merchandise:

- Ensure that your brand’s essence is captured in the design.

- Use durable materials that reflect the quality of your music.

Offering Extras like Gift Cards and Stickers

Extras to Consider:

- Download cards

- Exclusive content access

- Band stickers

Gift cards can serve as an excellent tool to strengthen your relationship with fans. They offer the flexibility for fans to choose their own vinyl variants or other merch, making the gift of music more personal.

Furthermore, including stickers in your vinyl packaging provides a small yet significant way for fans to show their support. Similar to how indie bands often include small keepsakes with their merch, your custom records can become part of a greater collection for your listeners.

Key Points to Remember for Extras:

- Custom records can be complemented by gift cards for a personalized shopping experience.

- Stickers add a fun, collectible element that allows fans to physically engage with your brand.

FAQs

Is it possible for me to press my own music onto vinyl?

Yes, you can press your own music onto vinyl either by using specialized vinyl cutting machines at home or by employing professional custom pressing services.

What equipment do I need to make vinyl records at home?

To make vinyl records at home, you need a vinyl cutting machine, blank vinyl discs, and audio mastering software, but be aware that this equipment can be costly and requires technical know-how.

How much does it cost to have a record custom pressed by a professional service?

The cost varies depending on the quantity, quality, and specific services required, but custom pressing typically starts from a few hundred dollars for a small batch.

Can I legally press any music onto vinyl?

You must own the rights to the music or have permission from the copyright holder to legally press music onto vinyl to avoid copyright infringement.

Will a vinyl record I make myself have the same quality as commercially produced ones?

DIY vinyl records may not match the sound quality of commercially pressed records due to differences in pressing techniques and equipment quality.